FlowFAST V 12

FlowFAST V are positive pressure ISO Class 3 vertical laminar flow cabinets which represent far more economical and valid alternatives to clean-rooms, as they are capable of providing uncontaminated, particle-free and sterile conditions for materials in the work-space.

They guarantee and maintain excellent product protection factors by offering a positive pressure particle-free working area by virtue of the G3 prefilter with a minimum efficiency of 80%-90% ASHRAE and the H 14 HEPA/ULPA filter with an efficiency better than 99,995 % MPPS (H14 – EN:1822).

FlowFAST V have been widely adopted in many sectors of industry and in science laboratories for use when handling no-risk cell cultures or non-pathogenic biological specimens when the aim is to provide a high degree of protection factor to the samples and the products on the worktop.

FlowFAST V have applications in a wide range of disciplines such as: quality control of pharmaceuticals and food/beverage industries, cell culture, sterile handling, PCR.

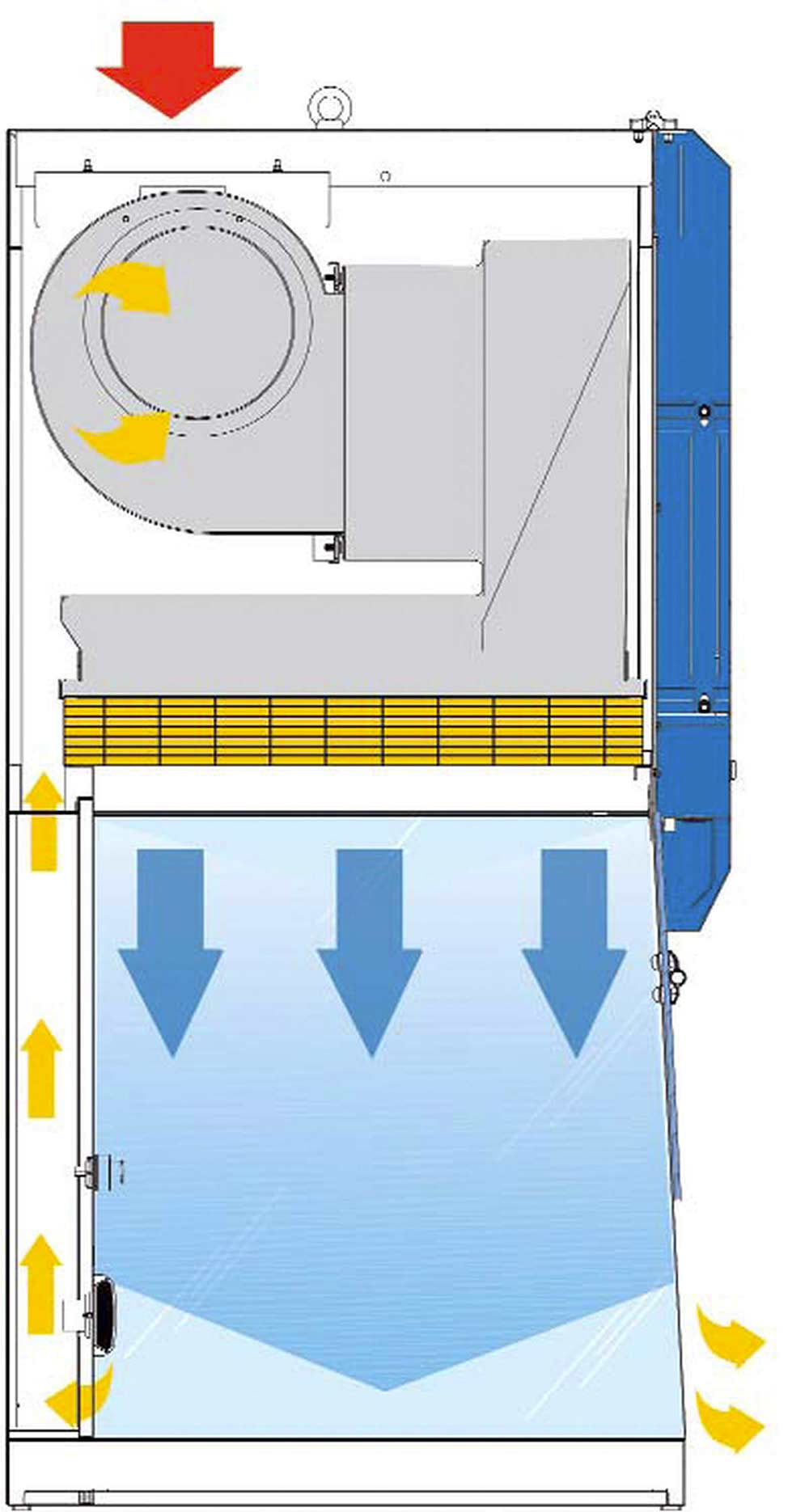

The environment air is drawn from the top of the cabinet via a G3 pre-filter and then pulled downwards and filtered by virtue of H14 HEPA/ULPA filter into the working area in positive pressure creating vertical laminar air flow pattern.

About half of the volume is exhausted outside into the environment and remaining volume is re-circulated by means of slots positioned at the bottom of the back panel.

Ergonomic Design: The angled sloping (7°) front hinged safety-glass provides optimum visibility of all objects placed in the interior workspace. The frontal opening is set to 200 mm. The whole front of the cabinet can also be opened upwards as it is hinged on the top – in order to allow easy access for complete and effective cleaning and decontamination.

Real Laminar AirFlow: Frontal screen 7° sloped as well as back side wall to convey in unidirectional pattern the air flow. As a consequence, the front and back panels are parallel one with the other and there is the real presence of Laminar AirFlow in the whole working area.

ECS® Eco Controling System: The new ECS® microprocessor employs the latest innovative methods of integrated management of all principal functions of ventilation and filtration – self-regulating all the main filtration and ventilation system components – compensating for declining pressure drops and restoring power balance. Combining the use of AC motor-blower and certified low pressure-drop filters, the new ECS® controlling system optimize power consumption, reducing CO2 emissions into the environment.

Anti Bacterial Coating: Exclusive Dupont™ ALESTA® anti-bacterial “Ag+ cations-based solution”, capable to prevent microbial contamination of surfaces thereby inhibiting long term surface growth.

High Level Lighting: The safety glass side-windows with the ideal positioning and sizing of the light-system provide the highest level of luminosity to the work area.

Easy handling and maintenance: The cabinet can pass through standard 800 mm wide door openings. In fact, the overall depth of the cabinet is 760mm. All service operations are available from the front of the cabinet. Useful snap hinges keep in open position the frontal tempered glass increasing the height of the frontal opening. This solution allows the entrance of devices (such as microscopes) beneath laminar flow.

Electrical sockets fitted as standard in each size model: one (for size 12) or two (for size 15 and 18).

External structure in epoxy powder coated cold-rolled steel for excellent corrosion resistance to the attack by aggressive common chemicals. Alternatively special models with external structure made in AISI 304L stainless steel for superior cleanability are also available on demand.

Rear wall in epoxy coated steel, designed to conform to requirements and pass the “cleanability test”.

Work surface in stainless steel AISI 304L fixed in one piece.

Front window: Stratified hinged safety glass to give easy access to large items. It is provided with gas springs to keep it open during maintenance or sanitization operations.

Filtration: H14 HEPA/ULPA filter with an efficiency better than 99,995 % MPPS (EN-1822).

Prefiltration: Inlet G3 pre-filter efficiency 80≤AM≤90 according to EN 779 and UNI 10339

Operation Condition: Air cleanliness in Class ISO 3 as per ISO:EN 14644-1.

Motor blower: direct coupled motor, electronic speed controlled to maintain a constant laminar air flow of 0.45 m/sec, and compensate for a partially clogged filter up to a maximum plenum pressure of 40 mm of water.

Servicing side glass with ports for service taps installation.

The user-friendly practical keyboard and the rear-lit LCD (optional) will continuously display all required data keeping the user constantly informed of the cabinet conditions in operation, and in particular:

- display of laminar airflow velocity

- display of inside and outside temperature

- display of residual lifetime of HEPA/ULPA filter, UV Lamp.

- display of total number of hours of operation

- display of saturation level of HEPA/ULPA filter

Audio-visual alarms (optional) provided for:

- out of range or incorrect laminar airflow velocity

- front window opened

- clogging of HEPA/ULPA filter

- end of life-cycle of UV lamp

- fan-motor malfunction

- power failure

Lighting: fluorescent tubes in built-in housing, placed outside the sterile area.

D.O.P.-DEHS inlet port for testing the HEPA/ULPA filters

Magnetic and removable UV sterilizing lamp (optional) that can be easily placed in each area of the back wall. It is completed with two switch-off countdown timers, one variable on a 0-3 hours scale (1 minute steps), the other set to 3 fixed hours.

| Code | F00001120000 |

| Width [cm] | 120 |

| Pressure | Positive |

| Motor Blower | Single fan |

| Technical Sheet | |

| Useful dimension (mm) [WxDxH] | 1198x609x755 |

| Overall dimension [mm] [WxDxH] | 1350x760x1545 |

| Noise Level (dbA) | <60 |

| Working aperture [mm] | 250 |

| Lightning level (lux) | >800 |

| Weight [kg] | 170 |

| Electrical data [230V – 50H] (**) | 230V – 50 Hz |